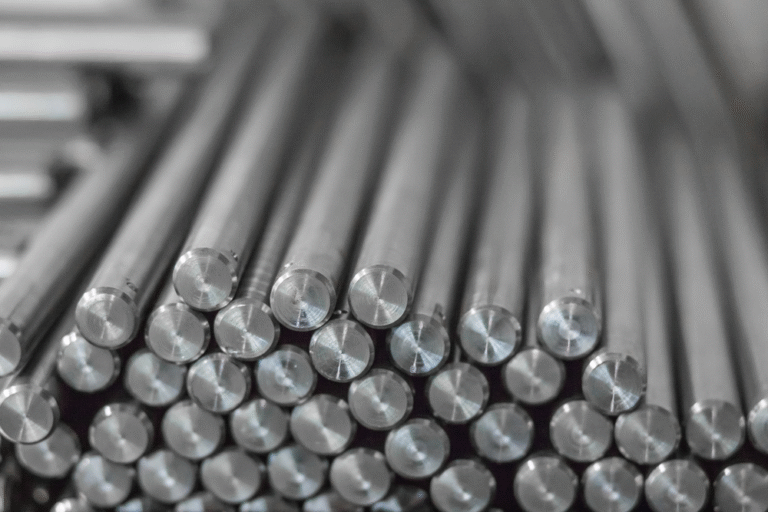

Illinois manufacturers rely heavily on Swiss machining for producing high-precision parts in industries such as medical, aerospace, and automotive. To achieve the best results, these machines require precision steel bars with consistent diameters, tight tolerances, and smooth finishes. Using the right bar stock ensures that every cut is accurate, cycle times are reduced, and tool wear is minimized.

Why Precision Steel Bars Are Essential for Swiss Machining

Swiss machining thrives on accuracy and efficiency, making the quality of raw material critical. Precision steel bars offer:

Tight Tolerances – ensuring perfect fit in machining operations.

Superior Straightness – reducing vibration and improving stability.

Smooth Surface Finish – minimizing secondary operations.

Consistent Hardness – allowing reliable performance during long production runs.

Industries in Illinois Using Swiss Machined Parts

Precision bars processed through Swiss machining serve a wide range of Illinois industries, including:

Medical – surgical screws, orthopedic implants, and custom devices.

Aerospace – pins, bushings, actuators, and high-tolerance engine parts.

Automotive – small precision shafts, fuel injector components, and drive pins.

Electronics & Industrial – connectors, fasteners, and micro-machined components.

Common Bar Stock Finishes for Swiss Machining

To meet industry needs, Illinois suppliers offer precision bars in multiple finishes:

Centerless Ground (CG)

Precision Ground (PG)

Cold Finished (CF)

Cold Drawn (CD)

Turned, Ground & Polished (TGP)

Precision Shaft Quality (PSQ)

These options ensure manufacturers can choose the right finish for both performance and cost efficiency.

Why Illinois Manufacturers Choose Local Suppliers

Partnering with a local Illinois supplier provides shorter lead times, access to in-stock materials, and reliable certifications. For industries like medical and aerospace, where compliance and quality are vital, working with a trusted source for Swiss machining bar stock ensures both performance and peace of mind.

Swiss Machining Precision Ground Bars Near Me

Swiss machining depends on precision ground bars to achieve flawless results. Illinois manufacturers across medical, aerospace, and automotive industries rely on centerless ground, TGP, cold drawn, and PSQ bar stock to meet today’s strict production demands. Choosing a specialized supplier means consistent quality, faster delivery, and a competitive advantage.