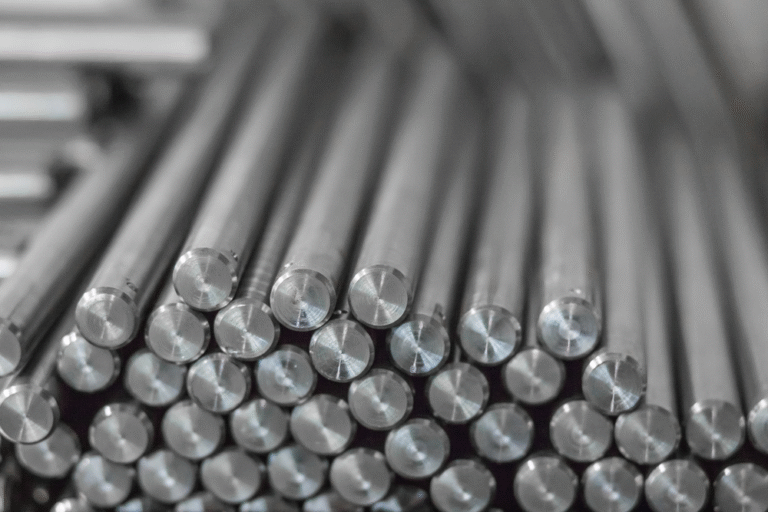

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Medical grade precision ground bars are the foundation of high-quality manufacturing in Indiana’s medical, aerospace, and advanced machining sectors. With the state’s strong presence in medical device production and industrial manufacturing, businesses demand bar stock that offers tight tolerances, smooth finishes, and superior material integrity.

Medical applications leave no room for error. Precision ground bars provide the dimensional accuracy and surface finish required for components such as implants, surgical tools, and custom devices. For Indiana manufacturers, these materials help streamline machining operations, reduce waste, and ensure compliance with industry standards.

Manufacturers in Indiana rely on a range of specialty metals to meet strict requirements:

Stainless Steel (316L, 17-4 PH) – corrosion-resistant and biocompatible.

Titanium Alloys – lightweight and strong, ideal for orthopedic parts.

Cobalt Chrome – high wear resistance for joint replacements.

Maraging Steels – ultra-high strength for aerospace and tooling.

Tool Steels (W1, O1, D2) – reliable for precision instruments.

These materials are often supplied in finishes such as centerless ground, cold drawn, TGP (Turned, Ground & Polished), CF (Cold Finished), and PSQ (Precision Shaft Quality).

Medical & Surgical – implants, surgical pins, and precision tools.

Aerospace – shafts, actuators, and engine parts requiring exact dimensions.

Automotive – high-performance shafts, rods, and drivetrain components.

General Manufacturing – custom machining and fabrications that demand accuracy.

Working with a trusted supplier like Mozaic Precision Metals ensures Indiana manufacturers have access to ISO-compliant processes, certified materials, and reliable turnaround times. Local sourcing reduces lead times and provides the competitive advantage of faster delivery.

Medical grade precision ground bars are critical to Indiana’s medical and aerospace industries, ensuring performance, accuracy, and long-term reliability. By choosing Mozaic Precision Metals, manufacturers gain a trusted partner for high-quality precision bar stock.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique