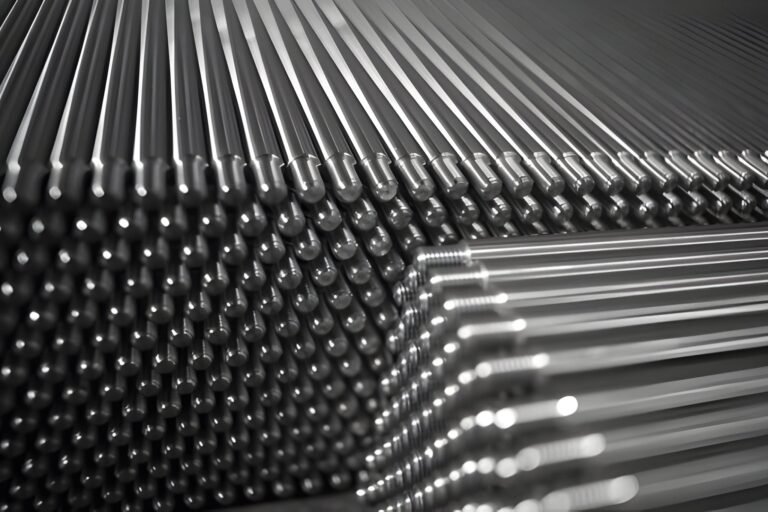

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Indiana has a strong base of medical, aerospace, and automotive manufacturers, many of which rely on Swiss machining to produce small, high-precision components. For these industries, the use of precision steel bars ensures accuracy, reduces cycle times, and improves part quality.

Swiss machining requires raw material with exceptional straightness, consistency, and finish. Precision steel bars provide:

Tight Tolerances – minimizing secondary machining.

Smooth Surface Finish – reducing tool wear and extending machine life.

Dimensional Stability – essential for micro-sized and intricate parts.

Reliable Machinability – helping manufacturers meet strict deadlines and quality standards.

Swiss machining with precision bar stock supports many sectors in Indiana, including:

Medical – surgical screws, orthopedic pins, and dental tools.

Aerospace – actuators, bushings, and precision fasteners.

Automotive – drive pins, fuel injector parts, and small shafts.

Industrial & Electronics – custom connectors, fittings, and miniature components.

Indiana manufacturers often use a variety of precision bar finishes to match performance requirements:

Centerless Ground (CG)

Precision Ground (PG)

Cold Finished (CF)

Cold Drawn (CD)

Turned, Ground & Polished (TGP)

Precision Shaft Quality (PSQ)

These finishes provide the accuracy and consistency Swiss machining demands.

Working with Mozaic Precision Metals gives Indiana manufacturers a trusted partner for sourcing certified precision bar stock. Local supply ensures shorter lead times, competitive pricing, and dependable quality — all vital for industries operating on tight tolerances and schedules.

Swiss machining depends on precision steel bars to achieve reliable, high-quality results. In Indiana, industries ranging from medical to aerospace benefit from the accuracy, consistency, and performance provided by Mozaic Precision Metals and its wide range of bar stock finishes.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique