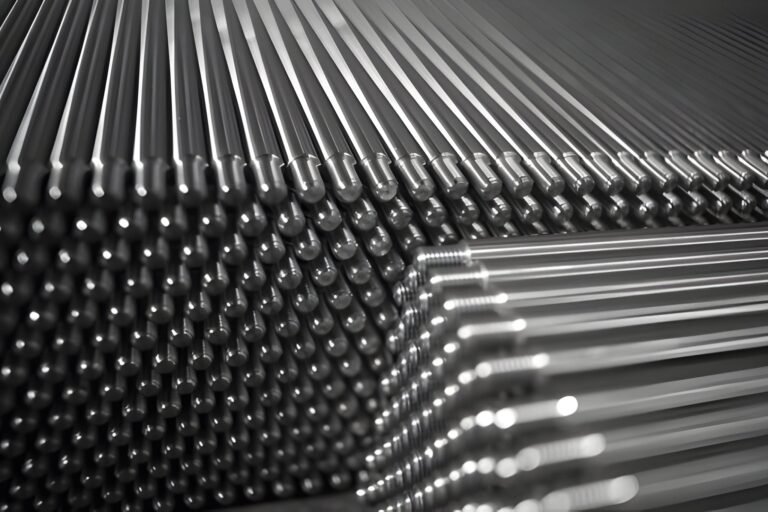

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Ohio’s aerospace, automotive, and medical manufacturers count on TGP (Turned, Ground & Polished) bars for parts that demand straightness, smooth finishes, and precise tolerances. These bars are widely used in shafts, rods, and machine components where vibration resistance and accuracy are critical.

TGP bars are cold finished steel bars that undergo a three-step process: turning, grinding, and polishing. This process improves roundness, dimensional accuracy, and surface finish, resulting in bars that deliver reliable performance under heavy stress and motion.

Automotive – steering shafts, drive shafts, and transmission parts.

Hydraulics – piston rods and cylinder shafts.

Aerospace – actuators, landing gear rods, and spindles.

Medical & Industrial – surgical equipment, custom tools, and precision machinery.

Ohio manufacturers prefer TGP bars for their:

Superior Straightness – reducing vibration and ensuring balance.

Tight Tolerances – minimizing costly machining time.

Smooth Surface Finish – extending tool and component life.

Dependable Consistency – trusted for high-volume production.

Working with Mozaic Precision Metals gives Ohio manufacturers access to certified, ISO-compliant TGP bars, reliable inventory, and competitive pricing. Local supply means faster delivery and consistent support for industries operating on strict deadlines.

TGP (Turned, Ground & Polished) bars are essential to Ohio’s automotive, aerospace, and medical sectors, where accuracy and performance cannot be compromised. By sourcing through Mozaic Precision Metals, Ohio manufacturers secure high-quality TGP bars with trusted service and fast turnaround.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique