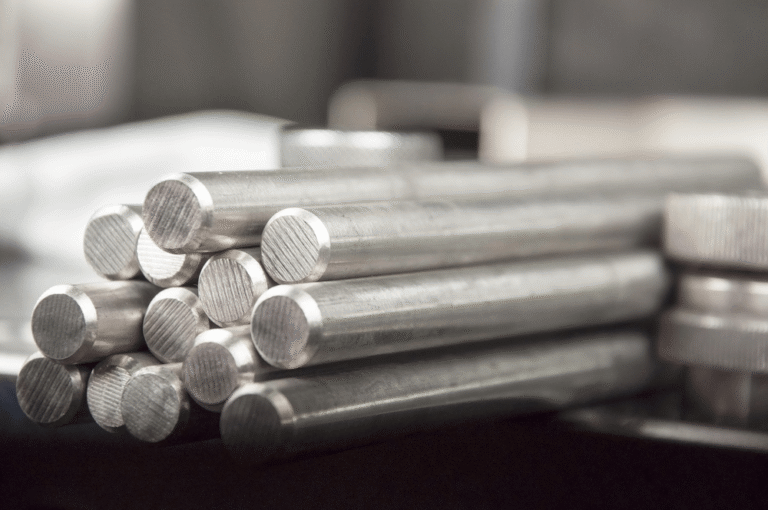

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Arkansas’s aerospace and defense manufacturing sector is growing rapidly, producing components for aircraft, turbines, and satellite systems. To meet these demanding requirements, manufacturers depend on centerless ground bars for their tight tolerances, excellent straightness, and smooth finishes that ensure flight-critical precision.

Aerospace components require accuracy and repeatability. Centerless ground bars provide:

Tight Tolerances – enabling precise fits and reducing rework.

Superior Roundness & Straightness – vital for rotating and sliding systems.

Smooth Surface Finishes – reducing friction and material fatigue.

Consistency – ensuring performance in extreme environments.

Actuator Shafts – delivering movement precision in aircraft systems.

Landing Gear Components – built to withstand impact and load stress.

Engine & Turbine Shafts – heat- and fatigue-resistant materials for reliability.

Bushings, Pins, and Fasteners – small, high-strength parts critical to flight safety.

Arkansas manufacturers source:

Titanium Alloys – lightweight with high strength-to-weight ratios.

Nickel Alloys (Inconel) – superior heat resistance for turbine applications.

Maraging Steels – ultra-high strength materials for structural integrity.

Stainless Steels (15-5 PH, 17-4 PH) – durable and corrosion-resistant.

Alloy Steels (4140, 4340, 9310) – fatigue-resistant for dynamic components.

With Mozaic Precision Metals, aerospace manufacturers in Arkansas gain ISO-certified centerless ground bars, certified alloys, and reliable lead times. This ensures on-time delivery and compliance with aerospace quality systems.

Centerless ground bars are crucial to Arkansas’s aerospace and defense industries, providing the precision, strength, and consistency required for mission-critical applications. Partnering with Mozaic Precision Metals guarantees certified bar stock that meets the highest performance standards.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique