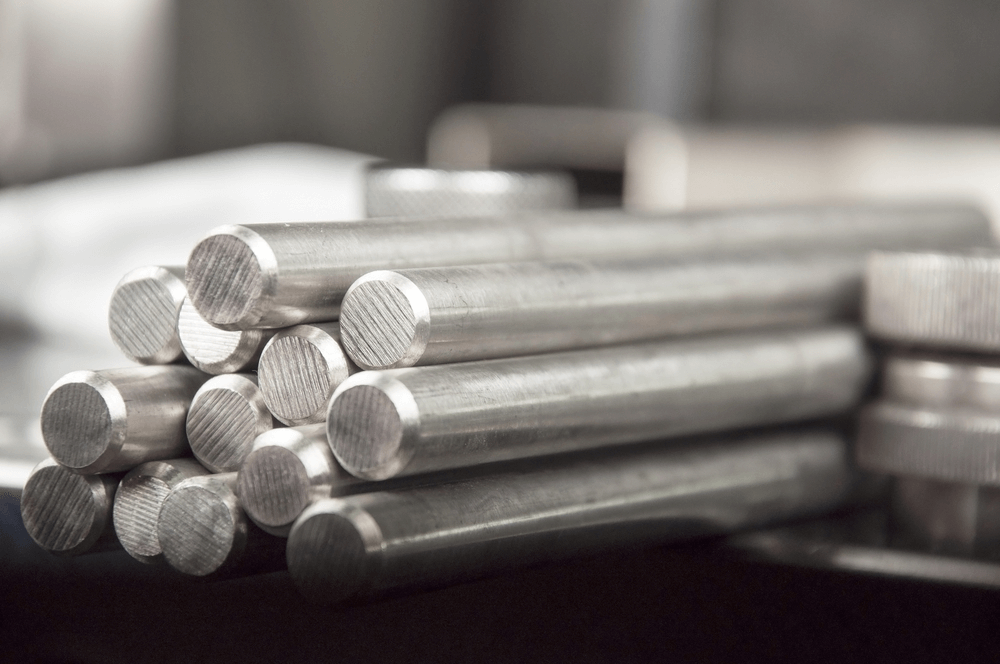

302 Stainless Steel: Tough, Versatile, and Built for Performance

When it comes to construction and manufacturing, material selection makes all the difference. One of the most trusted options is 302 stainless steel bar—a high-strength alloy engineered for durability and reliability. With its balanced blend of carbon, chromium, nickel, and other elements, 302 stainless delivers exceptional toughness for demanding applications ranging from heavy construction projects to precision aerospace components.

Why Choose 302 Stainless Steel Bar?

- Exceptional Strength – Despite its relatively thin profile, 302 stainless steel offers impressive toughness, making it a dependable choice for load-bearing and high-stress environments.

- High Ductility – This grade can be drawn into thin wire or formed into complex shapes without losing integrity, making it suitable for both structural and fine-detail applications.

- Corrosion Resistance – Built to withstand harsh conditions, 302 stainless resists rust and oxidation, making it ideal for outdoor, marine, and industrial settings.

Applications Across Industries

From construction and automotive parts to aerospace and marine equipment, 302 stainless round bar is valued for its ability to combine strength, ductility, and resistance to wear. It is a versatile material that adapts to both rugged environments and precision manufacturing requirements.

Conclusion

If you need a material that delivers toughness, versatility, and long-lasting performance, 302 stainless steel bar is the solution. Its unique combination of properties ensures dependable results in construction projects, industrial applications, and beyond.