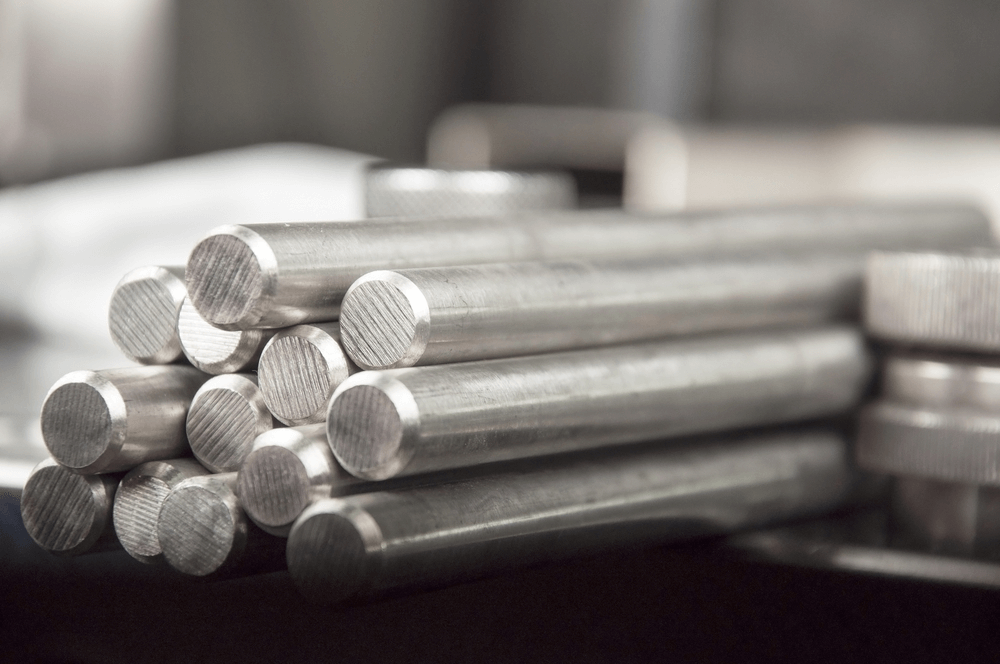

303 Stainless Steel Bar: Engineered for Superior Machinability

303 stainless steel round bar is a highly sought-after grade of austenitic stainless steel, recognized for its outstanding machinability. By adding sulfur to its composition, 303 stainless is specifically designed to reduce tool wear and improve cutting performance, making it the go-to choice for parts that require extensive machining.

Key Properties of 303 Stainless Steel

- Enhanced Machinability – Sulfur additions allow faster machining speeds, improved tool life, and cost-efficient production of complex components.

- Balanced Performance – While its corrosion resistance and toughness are slightly lower than other austenitic grades, 303 stainless still provides dependable strength and durability for most applications.

- Non-Magnetic Austenitic Structure – Like other grades in its family, 303 stainless steel is non-magnetic in the annealed condition, maintaining stability in specialized applications.

Applications of 303 Stainless Round Bar

Known for its machining advantages, 303 stainless bar stock is widely used to manufacture fittings, fasteners, shafts, gears, and precision components across industries including automotive, aerospace, food processing, and general manufacturing.

Choosing a Reliable Supplier

To maximize value, partner with trusted 303 stainless steel bar suppliers who specialize in delivering consistent quality, precise dimensions, and material traceability. With the right supplier, you can count on improved production efficiency and reliable end-use performance.

Conclusion

If your project demands a stainless steel grade that delivers superior machinability without sacrificing core durability, 303 stainless steel bar is the material of choice. It strikes the ideal balance between performance and ease of machining, making it a smart investment for cost-effective, high-quality parts.