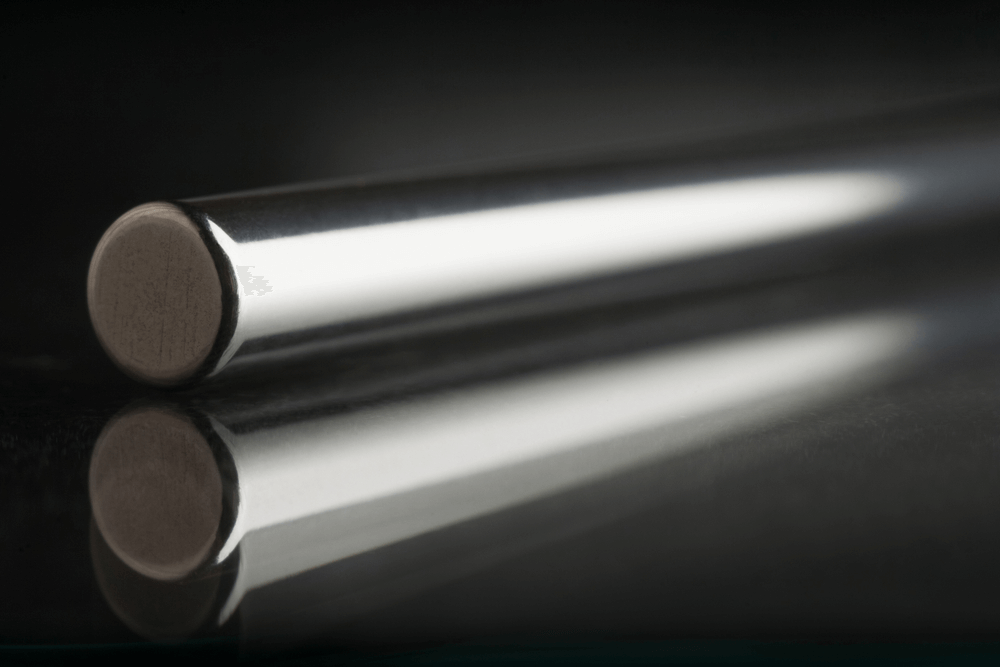

410 Stainless Steel: A Versatile and Corrosion-Resistant Alloy

410 stainless steel round bar is a martensitic stainless steel known for its balance of corrosion resistance, strength, and heat resistance. With approximately 11.5% chromium content, this alloy delivers dependable performance in environments requiring moderate corrosion protection and high mechanical strength.

Key Properties of 410 Stainless Steel

- Corrosion Resistance – Naturally resistant to rust and oxidation, with performance further enhanced by hardening, tempering, and polishing.

- High Strength & Heat Resistance – Performs reliably under mechanical stress and elevated temperatures when properly heat treated.

- Versatility – Available in multiple forms, including bar, wire, plate, and forgings, making it suitable for diverse applications.

- Machinability – Can be processed efficiently, particularly in its annealed condition.

Physical Properties of Annealed 410 Stainless Steel

- Density: 7800 kg/m³

- Elastic Modulus: 200 GPa

- Thermal Expansion (0–100°C): 9.9 µm/m·K

- Thermal Conductivity (at 500°C): 28.7 W/m·K

- Specific Heat (0–100°C): 460 J/kg·K

- Electrical Resistivity: 570 nΩ·m

Applications of 410 Stainless Steel Bar

Thanks to its strength, durability, and resistance to oxidation, 410 stainless bar stock is widely used in:

- Forgings and fasteners

- Wire and spring components

- Plates and structural parts

- Industrial equipment requiring moderate corrosion and heat resistance

Partner with Mozaic Precision Metals

At Mozaic Precision Metals, we provide precision-ground 410 stainless steel round bar in custom sizes and finishes. With services including grinding, polishing, cutting, and chamfering, we ensure your stainless bar meets the highest standards of accuracy and reliability.

For applications that demand a balance of corrosion resistance, strength, and heat performance, 410 stainless steel from Mozaic is a proven and versatile solution.