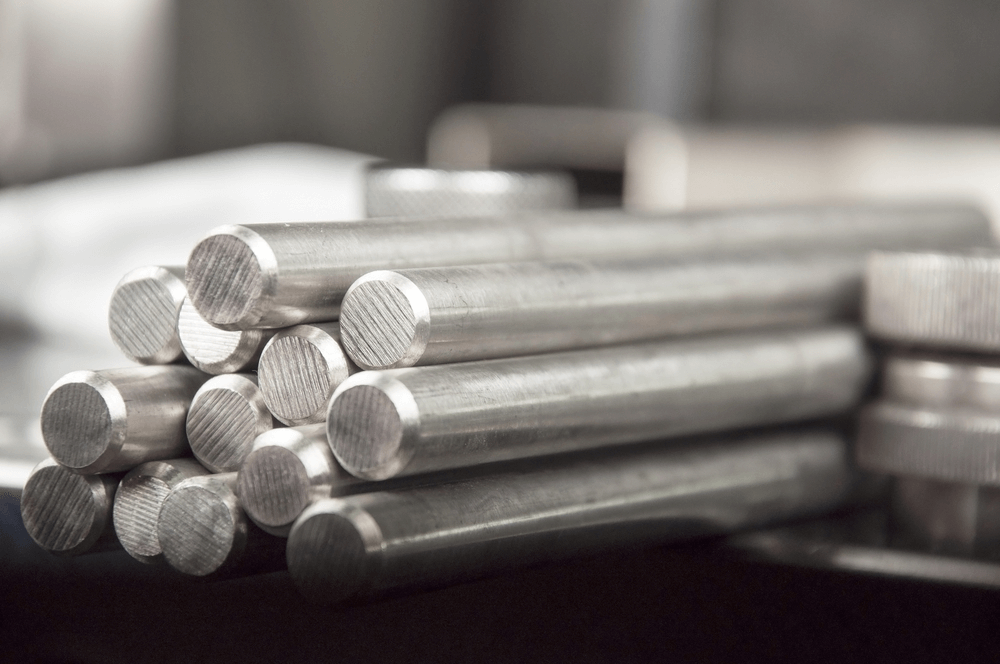

1018 Round Bar Stock: Reliable Choice for Multiple Applications

Although certain steels may offer higher strength or specialty properties, 1018 carbon steel remains widely used across industries for its excellent machinability, ease of fabrication, and cost-effectiveness. Its workability reduces expenses in grinding, machining, and production processes.

For applications requiring tight dimensional tolerances and a smooth surface finish, the cold-drawn 1018 round bar is the preferred option. This makes it a versatile material for components that demand precision and consistency.

At Mozaic Precision Metals, we supply premium 1018 carbon steel bars in both hot-rolled and cold-drawn forms, with the flexibility to meet your exact requirements. Whether you need bulk supply or custom sizes, our team ensures quality and precision every step of the way.

Partner with Mozaic Precision Metals for dependable 1018 round bar stock tailored to your industrial needs.