1215 Carbon Steel: Free-Machining Grade for Precision Manufacturing

1215 carbon steel is a low-carbon, resulfurized, and rephosphorized grade designed for superior machinability. With higher levels of phosphorus and sulfur, it delivers cleaner surface finishes, tighter tolerances, and reduced machining costs—making it a preferred alternative to 1018 carbon steel for precision work.

Key Characteristics of 1215 Carbon Steel

- Outstanding Machinability – Sulfur and phosphorus act as chip breakers, ensuring smooth cutting, reduced friction, and faster production cycles.

- Mechanical Strength – Offers moderate strength with a tensile range of 78,000–85,000 psi and a yield strength around 60,000 psi.

- Ductility & Toughness – Retains good toughness and high ductility for reliable performance in demanding applications.

- Wear Resistance – Provides reliable resistance against sliding and abrasive wear.

Applications of 1215 Carbon Steel

Thanks to its balance of machinability and strength, 1215 steel is commonly used to manufacture:

- Precision gears and bushings

- Couplings and fasteners

- Hydraulic fittings and shafts

- Studs and mechanical assemblies

- Custom machined parts requiring fine detail

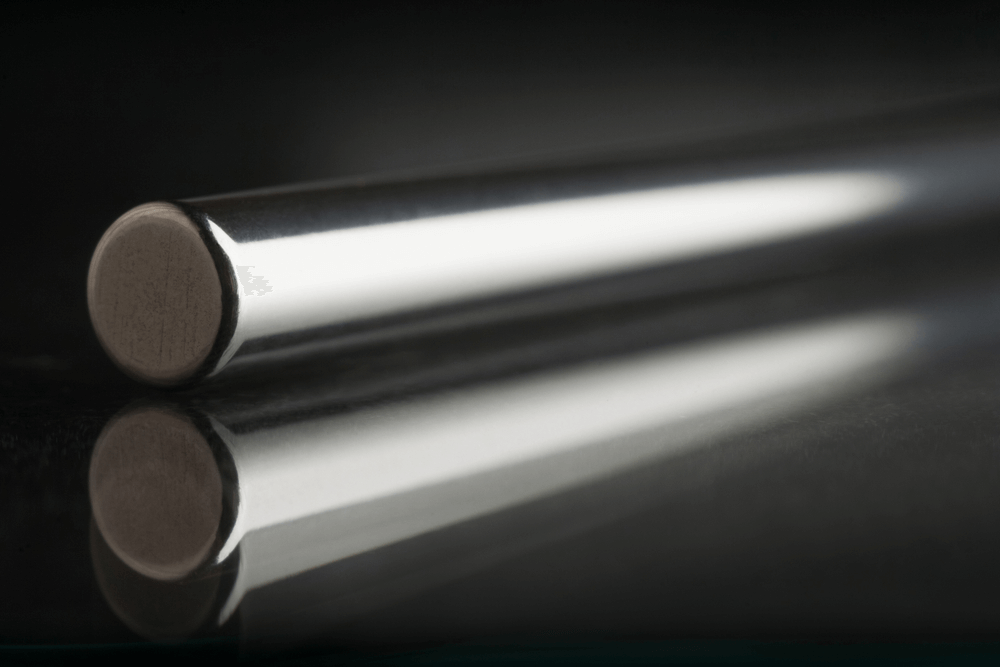

At Mozaic Precision Metals, we supply 1215 carbon steel round bar stock in a variety of sizes and finishes, ensuring you receive the right material for your machining and production needs.