The aerospace industry demands unmatched precision and reliability in every component. In Illinois, home to a strong manufacturing base and aerospace suppliers, centerless ground bars play a critical role in producing parts that must withstand extreme environments. From aircraft actuators to landing gear shafts, aerospace applications rely on bar stock that delivers tight tolerances, flawless finishes, and proven strength.

Why Aerospace Relies on Centerless Ground Bars

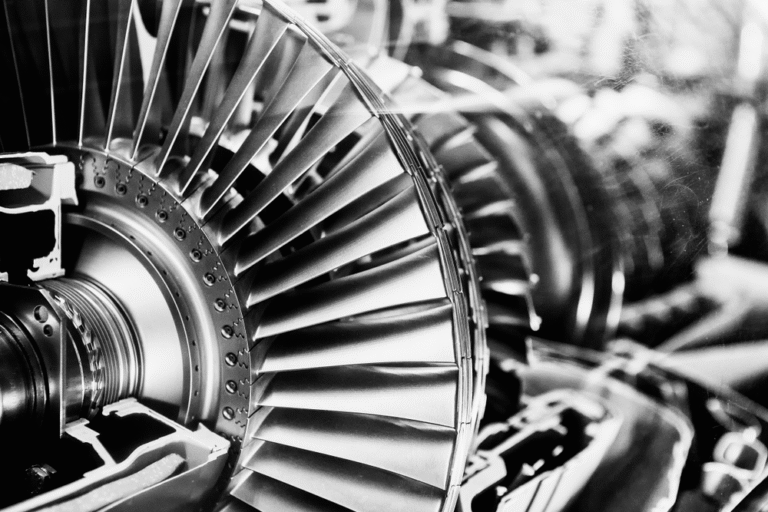

Aerospace parts face high stress, extreme temperatures, and constant motion. Centerless grinding provides consistent diameters, smooth surface finishes, and superior straightness, which are essential in reducing vibration, increasing lifespan, and ensuring flawless performance in mission-critical applications.

Key Aerospace Components Made from Precision Ground Bars

In Illinois aerospace manufacturing, precision ground bar stock is commonly used for:

Actuator Shafts – ensuring smooth and reliable movement of flight systems.

Landing Gear Components – where strength and dimensional accuracy are non-negotiable.

Engine Parts – requiring heat resistance and wear resistance under extreme conditions.

Pins, Bushings, and Fasteners – small but critical components that must maintain exact tolerances.

Materials Used for Aerospace Applications in Illinois

Different alloys are chosen based on strength, corrosion resistance, and weight requirements:

Titanium & Titanium Alloys – lightweight yet extremely strong, ideal for airframe and engine components.

Inconel & Nickel Alloys – high heat resistance, perfect for jet engines and turbine parts.

Maraging 300 Steel – ultra-high strength with excellent toughness.

Stainless Steels (15-5 PH, 17-4 PH) – corrosion resistant, used in shafts, rods, and fasteners.

Alloy Steels (4340, 9310) – valued for toughness and fatigue resistance.

Illinois Aerospace Industry and Local Demand

Illinois is strategically located with suppliers serving both military and commercial aerospace sectors. From small precision machining shops to major aerospace contractors, businesses here depend on reliable centerless ground bar suppliers that can provide certified material, ISO-compliant processes, and fast turnaround.

Aerospace Centerless Ground Bars - Conclusion

Centerless ground bars are indispensable in Illinois aerospace manufacturing. With their dimensional precision, superior surface quality, and material performance, they ensure safety and efficiency in the sky. Choosing a trusted Illinois supplier guarantees reliable sourcing for aerospace-grade bars in titanium, Inconel, stainless steel, and high-strength alloys.