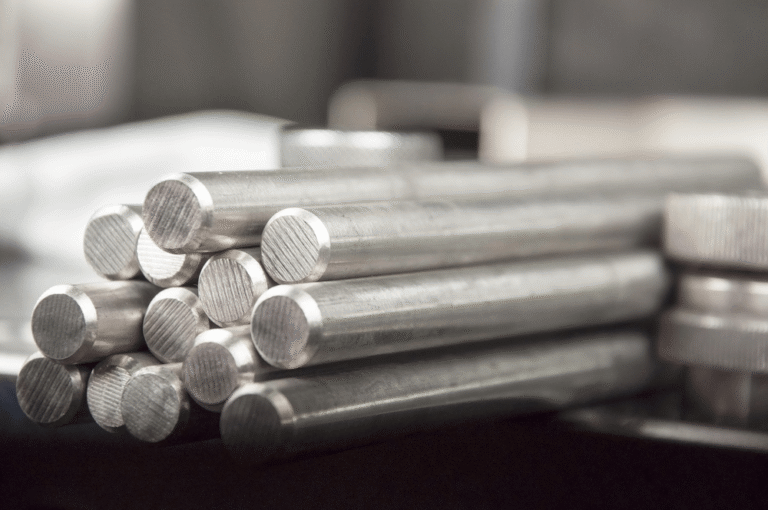

Indiana plays a key role in the aerospace supply chain, providing parts and machining services that support both commercial aviation and defense contractors. At the center of many of these operations are centerless ground bars, valued for their tight tolerances, roundness, and superior surface finish. From actuator shafts to landing gear components, these bars ensure reliability in flight-critical applications.

Why Aerospace Manufacturers Use Centerless Ground Bars

Centerless ground bars are chosen for aerospace applications because they deliver:

Consistent Diameters – vital for reducing vibration and ensuring part stability.

Superior Surface Quality – extends component life and improves performance.

Straightness and Roundness – essential for rotating or sliding parts under stress.

Reduced Machining Time – saves costs and speeds up production.

Key Aerospace Parts Made with Precision Bar Stock

In Indiana, aerospace suppliers use centerless ground bars for:

Actuator Shafts – providing precise movement in flight control systems.

Landing Gear Components – high-strength parts that must withstand heavy loads.

Engine Components – resistant to high temperatures and stress.

Pins, Bushings, and Fasteners – small but critical parts requiring accuracy.

Materials for Aerospace-Grade Bars

Aerospace applications demand high-performance alloys, including:

Titanium and Titanium Alloys – lightweight and strong for structural components.

Inconel & Nickel Alloys – excellent heat resistance for turbine parts.

Maraging 300 Steel – ultra-high strength for shafts and tooling.

Stainless Steels (15-5 PH, 17-4 PH) – corrosion-resistant and reliable.

Alloy Steels (4340, 9310) – fatigue-resistant and tough for aerospace loads.

Why Indiana Manufacturers Choose Local Supply

Partnering with a local supplier like Mozaic Precision Metals ensures Indiana aerospace companies receive certified, ISO-compliant bar stock with quick turnaround. This reduces delays, improves quality assurance, and guarantees dependable sourcing for critical aerospace components.

Precision Ground Bar Supplier for Aerospace

Centerless ground bars are indispensable in Indiana’s aerospace industry, offering the precision, strength, and finish required for mission-critical parts. With access to certified materials and fast delivery, Mozaic Precision Metals supports aerospace manufacturers in achieving consistent quality and reliability.