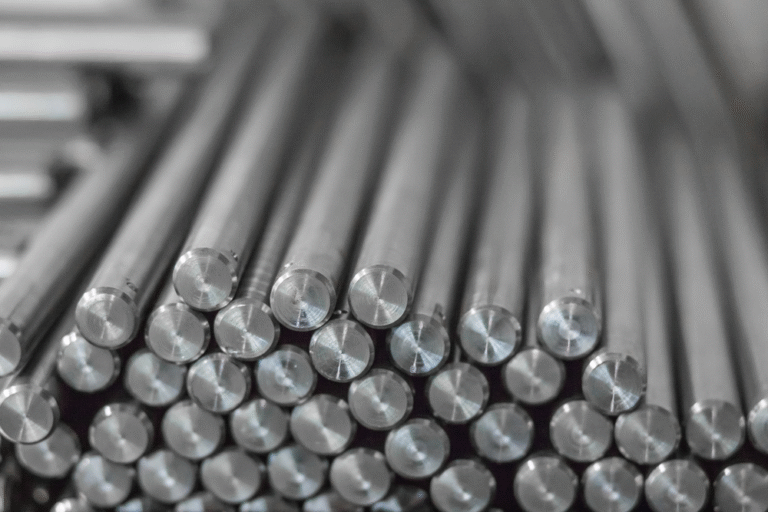

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Indiana’s medical and aerospace sectors rely on parts that demand precision, reliability, and consistency. Centerless ground bars provide the tight tolerances, straightness, and superior surface finish needed to manufacture everything from surgical tools to aerospace shafts. For manufacturers across the state, these bars are an essential material for mission-critical applications.

Centerless grinding produces bar stock with:

Tight Tolerances – for parts that must meet exact specifications.

Superior Roundness & Straightness – reducing vibration and improving part stability.

Excellent Surface Finish – minimizing secondary operations.

Consistency – reliable performance across production runs.

In the medical field, centerless ground bars are used for:

Orthopedic Implants – rods, pins, and surgical screws.

Dental Instruments – precision tools requiring smooth finishes.

Surgical Tools – scalpels, handles, and cutters.

Custom Medical Devices – components requiring both biocompatibility and accuracy.

For Indiana’s aerospace manufacturers, centerless ground bars are critical in:

Actuator Shafts – providing smooth and precise movement.

Landing Gear Parts – requiring strength and dimensional reliability.

Engine Components – designed to withstand extreme stress and temperatures.

Fasteners, Pins, and Bushings – ensuring accuracy and durability in flight.

Partnering with Mozaic Precision Metals gives Indiana manufacturers access to an extensive inventory of certified bar stock, including stainless steel, titanium, Inconel, and specialty alloys. Local sourcing provides shorter lead times, competitive pricing, and ISO-compliant quality standards.

Centerless ground bars are indispensable to Indiana’s medical and aerospace industries, providing the accuracy, finish, and performance required for high-stakes applications. With Mozaic Precision Metals as a trusted supplier, Indiana manufacturers gain consistent quality, fast turnaround, and reliable certification.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique