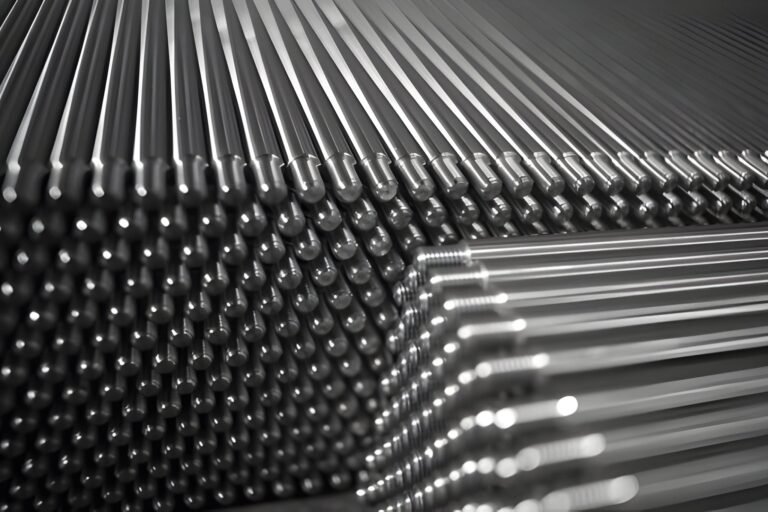

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Missouri’s medical and aerospace industries are recognized for their high standards of precision and safety. Centerless ground bars play a critical role in meeting these standards, providing the tight tolerances, smooth finishes, and straightness required for surgical instruments, implants, aircraft shafts, and turbine parts.

Centerless grinding produces bar stock with:

Tight Tolerances – ensuring accuracy and reducing machining time.

Exceptional Roundness & Straightness – ideal for rotating and sliding parts.

Smooth Surface Finishes – minimizing friction and improving part longevity.

Consistency – ensuring repeatable performance across production runs.

Orthopedic Implants – surgical pins, rods, and screws.

Surgical Tools – scalpels, drills, and precision cutters.

Dental Devices – implants and instruments requiring biocompatibility.

Custom Medical Components – engineered with exact tolerances.

Actuator Shafts – enabling precise aircraft control.

Landing Gear Components – built to withstand heavy loads.

Engine & Turbine Shafts – requiring heat- and fatigue-resistant alloys.

Bushings, Pins, and Fasteners – critical for structural reliability.

Missouri manufacturers source:

Stainless Steels (316L, 17-4 PH, 15-5 PH)

Titanium Alloys

Nickel Alloys (Inconel)

Cobalt Chrome

Tool Steels (W1, O1, D2)

Alloy Steels (4140, 4340, 9310)

By working with Mozaic Precision Metals, Missouri manufacturers gain access to ISO-certified centerless ground bars, certified alloys, and reliable lead times. This ensures projects meet strict performance and compliance requirements.

Centerless ground bars are essential for Missouri’s medical and aerospace sectors, delivering the precision, durability, and finish required for life-saving and flight-critical components. With Mozaic Precision Metals, companies gain a trusted partner for certified bar stock.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique