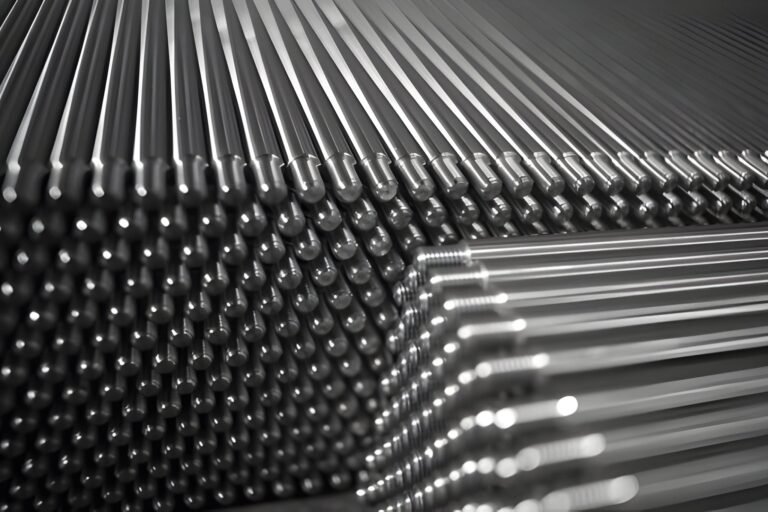

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Arkansas’s automotive, aerospace, and industrial manufacturers rely on cold drawn steel bars for their strength, dimensional accuracy, and machinability. These bars are a step above hot-rolled steel, offering tighter tolerances, higher tensile strength, and smoother finishes, making them ideal for precision applications.

Cold drawn steel bars are produced by pulling hot-rolled bars through a die at room temperature. This cold working process increases dimensional accuracy, surface quality, and strength, resulting in bar stock perfectly suited for machining, shafts, and high-stress components.

Medical – orthopedic rods, surgical tools, and custom instruments.

Automotive – axles, shafts, and drivetrain parts.

Aerospace – turbine shafts, actuator pins, and precision fittings.

Energy & Oilfield – pump shafts, hydraulic rods, and drilling tools.

Manufacturing & Fabrication – spindles, arbors, and machine components.

Arkansas manufacturers use cold drawn bars for:

Higher Strength – improved mechanical properties under stress.

Tight Tolerances – reducing finishing time in machining.

Smooth Surface Finishes – minimizing friction and wear.

Consistency – ensuring predictable results for precision parts.

By sourcing from Mozaic Precision Metals, Arkansas companies gain access to ISO-certified cold drawn steel bars, certified alloys, and fast delivery. Our consistent supply helps local manufacturers meet deadlines without sacrificing quality.

Cold drawn steel bars are essential to Arkansas’s precision manufacturing industries, offering the strength, accuracy, and finish needed for top-quality components. Partnering with Mozaic Precision Metals guarantees reliable bar stock and long-term performance.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique