11L17 Steel: Free-Machining Carbon Steel for Precision Components

11L17 steel is a low-carbon, resulfurized, and rephosphorized grade specifically designed for exceptional machinability. With about 0.17% carbon, 0.80% manganese, and controlled amounts of sulfur and phosphorus, it belongs to the family of free-machining steels widely used in precision manufacturing.

Key Properties of 11L17 Steel

- Enhanced Machinability – Sulfur and phosphorus form small inclusions that reduce cutting friction, making it easier to drill, cut, and shape.

- Good Carburizing Properties – Allows surface hardening while retaining a ductile core, ideal for wear resistance.

- Improved Hardness & Strength – Manganese increases hardenability and contributes to overall strength.

- Cost-Effective Production – Reduces machining time, tool wear, and overall manufacturing costs.

Common Applications of 11L17 Steel

Thanks to its balance of machinability and performance, 11L17 steel is widely used in producing small to medium-sized components, including:

- Bolts, nuts, and screws

- Fittings and couplings

- Hydraulic components

- Bushings and sleeves

- Automotive and machinery parts requiring precision machining

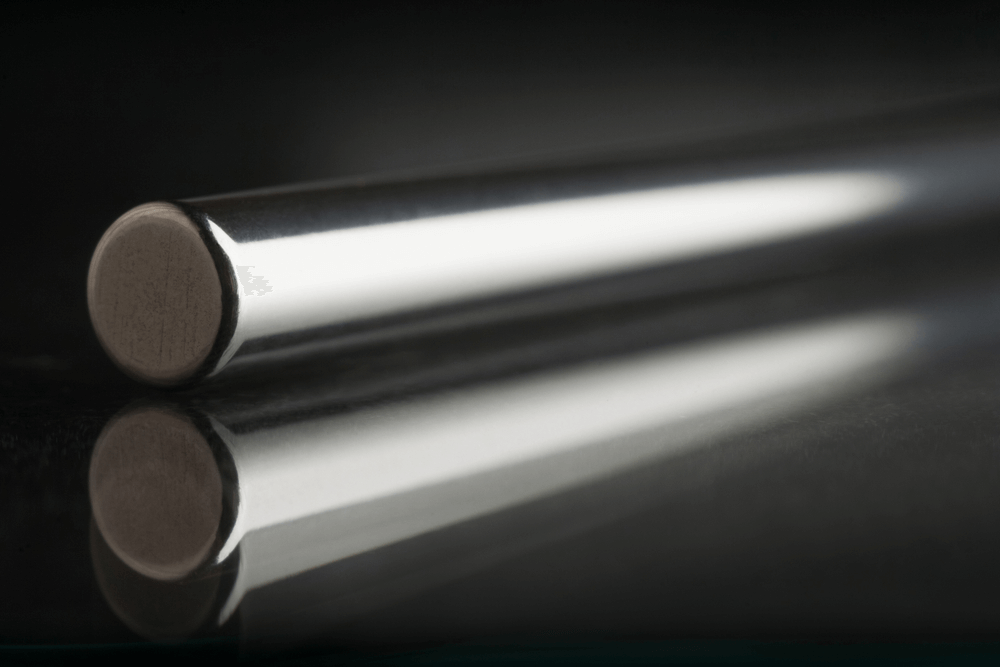

At Mozaic Precision Metals, we supply high-quality 11L17 round bar stock engineered for efficiency in machining and consistency in performance—helping you achieve accurate results in every project.