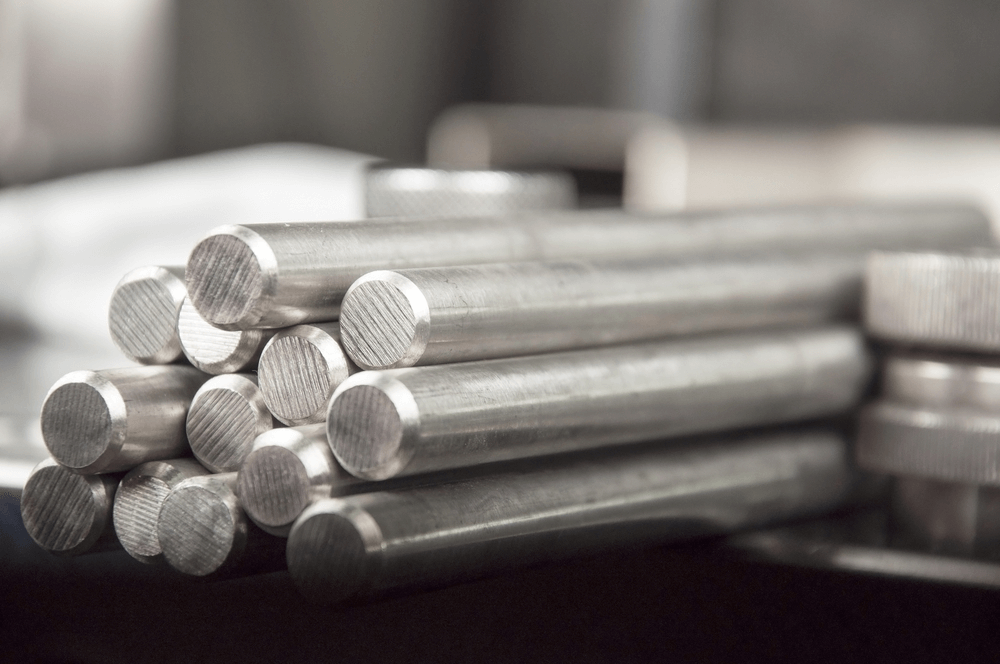

All You Need to Know About 15-5PH Stainless Steel Bar

15-5PH stainless steel bar, also known as 15-5 round bar, is a martensitic precipitation-hardening stainless steel recognized for its combination of high strength, toughness, and excellent corrosion resistance. Containing approximately 15% chromium and 5% nickel, this alloy is widely used across aerospace, defense, oil & gas, and construction industries.

Key Properties of 15-5PH Stainless Steel

- High Strength & Hardness – Delivers exceptional tensile strength and wear resistance, even in demanding environments.

- Corrosion Resistance – Performs reliably in marine, chemical, and industrial applications where exposure to corrosive elements is common.

- Heat Treatable – A single low-temperature heat treatment enhances transverse toughness, ductility, and forgeability, especially in larger cross-sections.

- Machinability – Can be machined effectively in a variety of thermal conditions, improving production efficiency.

Chemical Composition of 15-5PH Stainless Steel

The alloying elements that give 15-5PH its strength and corrosion resistance include:

- Chromium: 14.00 – 15.50%

- Nickel: 3.50 – 5.50%

- Copper: 2.50 – 4.50%

- Columbium + Tantalum: 0.15 – 0.45%

- Manganese: 1.00% max

- Silicon: 1.00% max

- Carbon: 0.07% max

- Sulfur: 0.030% max

- Phosphorus: 0.040% max

Applications of 15-5PH Stainless Steel Bar

Thanks to its mechanical performance and corrosion resistance, 15-5PH bar stock is widely used in:

- Aerospace structural components

- Valves, gears, and shafts

- Nuclear reactor components

- Oil & gas equipment

- Construction beams and reinforced concrete structures

Partner with Mozaic Precision Metals

At Mozaic Precision Metals, we supply high-quality 15-5PH stainless steel bar in various sizes and finishes. Our precision services—including grinding, polishing, cutting, and chamfering—ensure every bar meets the strictest standards of accuracy and performance.

For projects requiring strength, durability, and resistance to corrosion, 15-5PH stainless steel from Mozaic is a proven, cost-effective solution.