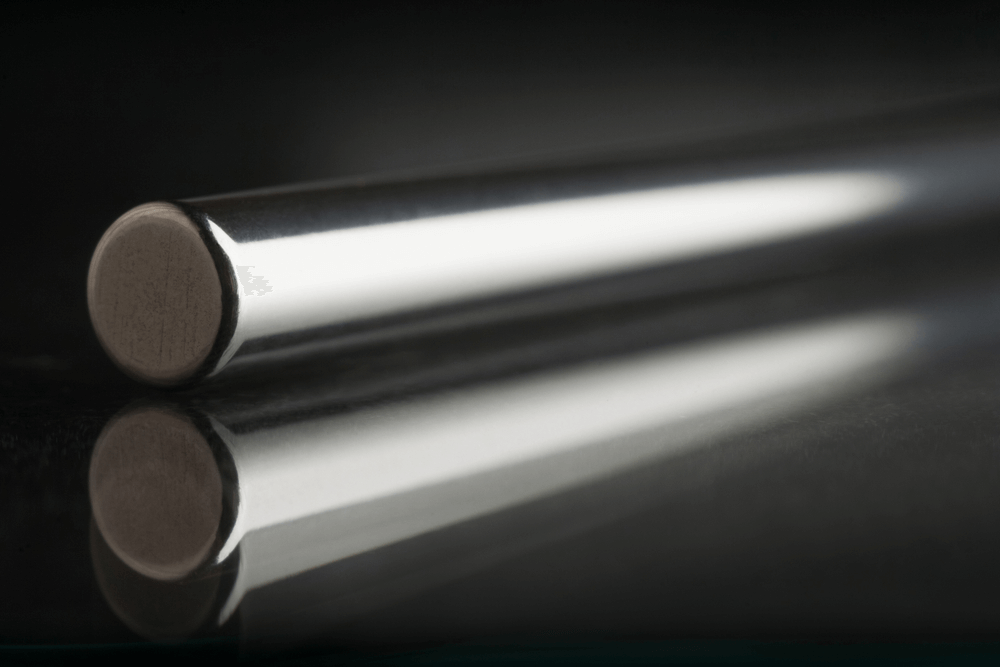

Quality 304 Stainless Steel Round Bar Stock

304 stainless steel round bar is one of the most widely used austenitic grades, known for its excellent corrosion resistance, durability, and formability. Its ability to be severely deep drawn makes it the dominant stainless grade for applications such as saucepans, sinks, and other kitchen equipment, as well as structural and industrial uses.

Chemical Composition of 304 Stainless Steel

The balanced alloying elements of 304 stainless bar stock provide strength, ductility, and excellent corrosion resistance:

- Carbon (C): 0.00 – 0.07%

- Manganese (Mn): 0.00 – 2.00%

- Silicon (Si): 0.00 – 1.00%

- Phosphorus (P): 0.00 – 0.05%

- Sulfur (S): 0.00 – 0.03%

- Chromium (Cr): 17.50 – 19.50%

- Nickel (Ni): 8.00 – 10.50%

- Nitrogen (N): 0.00 – 0.11%

- Iron (Fe): Balance

Mechanical Properties of 304 Stainless Bar Stock

- Tensile Strength: 540 – 750 MPa

- Proof Stress: ≥ 230 MPa

- Elongation (A50mm): ≥ 45%

Physical Properties of 304 Stainless Steel

- Density: 8.00 g/cm³

- Melting Point: 1450°C

- Modulus of Elasticity: 193 GPa

- Electrical Resistivity: 0.72 × 10-6 Ω·m

- Thermal Conductivity: 16.2 W/m·K

- Thermal Expansion: 17.2 × 10-6/K

Applications of 304 Stainless Steel Round Bar

With its balance of corrosion resistance, strength, and workability, 304 stainless steel bar stock is used across industries for:

- Kitchen equipment including sinks, cookware, and utensils

- Architectural and structural components

- Automotive and aerospace parts

- Pumps, valves, and industrial machinery

Partner with Mozaic Precision Metals

At Mozaic Precision Metals, we supply high-quality 304 stainless steel round bar with precision finishing options including grinding, polishing, cutting, and chamfering. Our expertise ensures every bar meets strict performance and dimensional requirements for your application.

For industries requiring a versatile, corrosion-resistant, and cost-effective stainless alloy, 304 stainless steel from Mozaic is the proven standard.