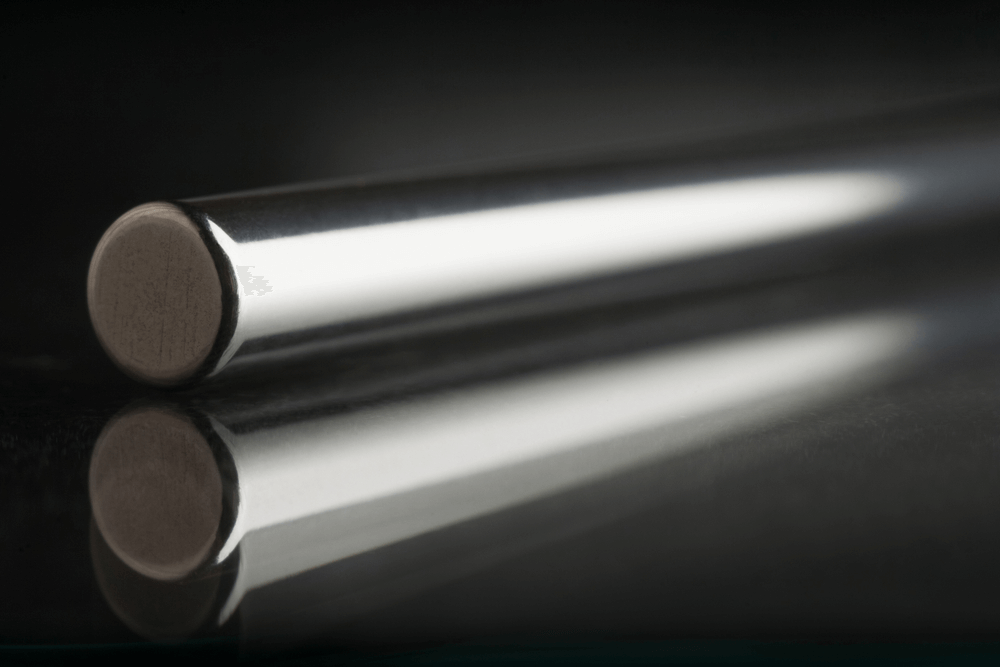

440F Stainless Steel Bar: Strength with Corrosion Resistance

440F stainless steel is a martensitic alloy designed for applications requiring high strength, wear resistance, and moderate corrosion resistance. Containing a minimum of 10% chromium, this alloy offers durability in challenging environments while maintaining good machinability due to its sulfur content.

Performance Characteristics of 440F Stainless Steel

- Corrosion Resistance: Withstands many corrosive environments, making it suitable for components exposed to moisture and mild chemicals.

- High Strength: Offers excellent tensile and yield strength, providing durability for demanding applications.

- Machinability: Sulfur additions improve machinability compared to other 440 stainless grades, making it easier to work with.

- Temperature Limitations: Not recommended for prolonged high-temperature use, as over-tempering can reduce ductility and toughness. Performance may also decline at very low temperatures (below 0°C).

Applications of 440F Stainless Steel Bar

440F stainless bar stock is widely used in applications where strength and corrosion resistance are both critical. Common uses include:

- Valves and pump shafts

- Fasteners and precision components

- Automotive and aerospace hardware

- Machine parts requiring both wear resistance and machinability

440F Stainless Steel from Mozaic Precision Metals

At Mozaic Precision Metals, we provide precision-ground 440F stainless steel bars tailored to your specifications. With over 60 years of combined leadership experience in precision grinding, our team ensures you receive consistent quality and dependable performance for every order.

Looking for reliable stainless steel bar stock? Request a custom quote today and partner with Mozaic Precision Metals for high-performance stainless solutions.