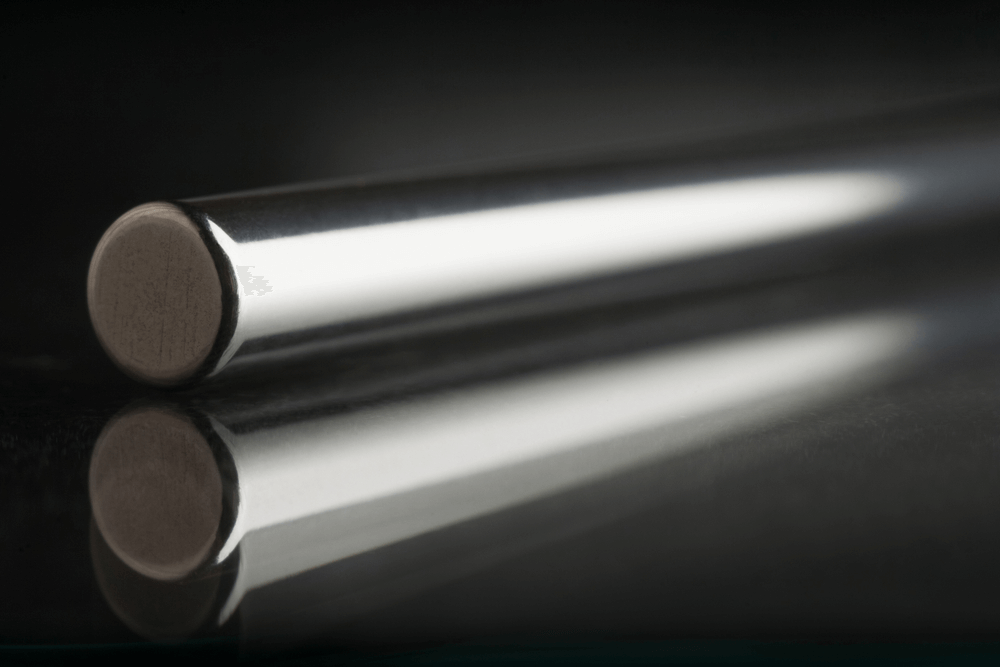

What is Inconel 718 Bar?

Inconel 718 bar is a nickel-chromium superalloy recognized for its outstanding strength, toughness, and resistance to extreme heat and corrosion. It delivers exceptional yield, tensile, and creep-rupture properties at elevated temperatures while maintaining excellent fabricability and weldability in both annealed and precipitation-hardened conditions.

The Workhorse of Superalloys

Known as the “workhorse” of superalloys, Inconel 718 is one of the most widely used high-performance materials across critical industries. Its unique alloying elements give it remarkable resistance to oxidation, acidity, and alkalinity, ensuring long service life in demanding environments.

Applications of Inconel 718 Bar

Mozaic Precision Metals supplies Inconel 718 bar stock for industries where components are continuously exposed to heat, pressure, and corrosive environments. Common applications include:

- Aerospace engines and turbine components

- Power generation equipment

- Oil and gas exploration tools

- Chemical processing systems

- High-temperature fasteners and structural parts

With its proven reliability, Inconel 718 bar remains a preferred choice for manufacturers who demand performance under the toughest operating conditions.