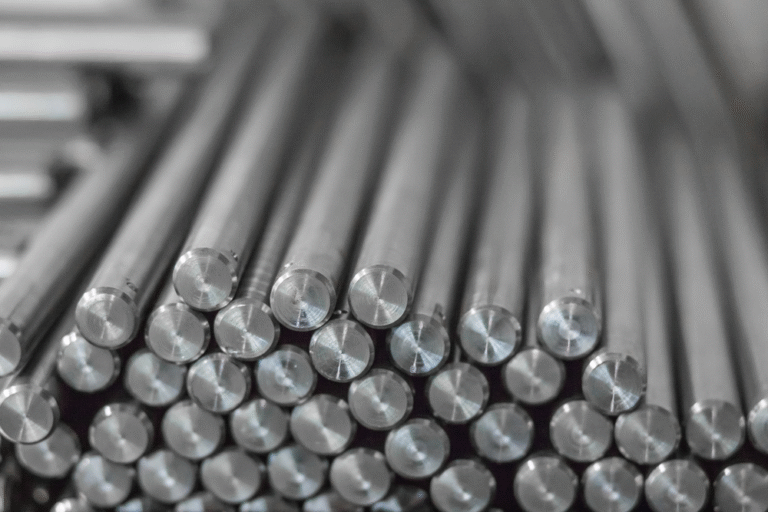

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Arkansas’s medical, aerospace, and industrial manufacturers depend on Swiss machining for small, high-precision components. This process requires precision steel bars that provide tight tolerances, excellent straightness, and smooth surface finishes — ensuring every part meets strict specifications.

Swiss machining is built for complex parts and close tolerances. Precision steel bars make that possible by providing:

Tight Tolerances – minimizing rework and improving production speed.

Exceptional Straightness – reducing vibration and maintaining tool alignment.

Smooth Surface Finishes – extending tool life and improving part quality.

Reliable Consistency – supporting repeatable results across production runs.

Medical – surgical pins, orthopedic screws, and dental implants.

Aerospace – precision fasteners, actuator rods, and turbine bushings.

Automotive – shafts, pins, and precision fittings.

Energy & Oilfield – connectors, pump components, and high-pressure fittings.

Arkansas manufacturers use bar stock in finishes such as:

Centerless Ground (CG)

Precision Ground (PG)

Cold Finished (CF)

Cold Drawn (CD)

Turned, Ground & Polished (TGP)

Precision Shaft Quality (PSQ)

Each finish ensures accuracy and smooth performance during Swiss machining.

By partnering with Mozaic Precision Metals, Arkansas manufacturers gain ISO-certified precision steel bars, certified alloys, and consistent supply. This guarantees quality and reliability across aerospace, medical, and industrial production lines.

Swiss machining in Arkansas relies on precision steel bars to meet the tight tolerance and surface finish demands of today’s precision industries. With Mozaic Precision Metals, companies gain a dependable supplier for certified, high-quality bar stock.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique