Illinois manufacturers depend on TGP (Turned, Ground & Polished) bars for applications that require straightness, dimensional consistency, and long-term performance. From aerospace suppliers around Chicago to hydraulic and heavy equipment builders across the state, TGP material supports parts where precision cannot vary.

The Role of TGP (Turned, Ground & Polished) Bars in Precision Manufacturing

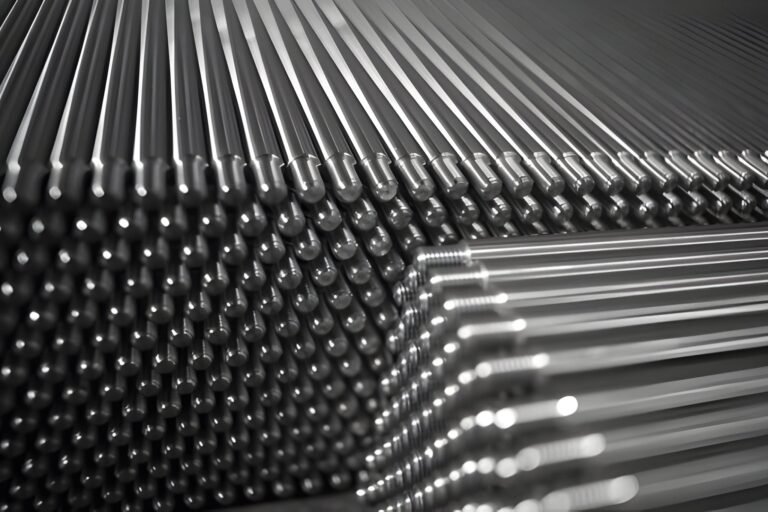

TGP bar stock is produced through a controlled finishing sequence that improves the geometry and performance of the material. Turning removes surface irregularities, precision grinding refines size and roundness, and polishing enhances surface condition and wear resistance.

This multi-stage process produces bar stock suited for rotating components, load-bearing assemblies, and motion-driven systems.

Key Illinois Industries Using TGP Bar Stock

Illinois has one of the strongest manufacturing bases in the Midwest, and TGP bars are used across multiple sectors:

Automotive and transportation

Steering shafts, drivetrain components, and machined pins used in high-load environments.

Hydraulics and heavy equipment

Cylinder rods, piston shafts, and motion-control components.

Aerospace and defense suppliers

Actuator rods, landing components, and structural precision shafts.

Medical device manufacturing

Surgical tooling, instrumentation, and precision mechanical parts.

Industrial machinery production

Pump shafts, automation components, and wear-resistant mechanical assemblies.

Performance Advantages of TGP Bars

Manufacturers specify TGP bar stock when performance and machining efficiency are critical.

Benefits include:

Improved straightness for better alignment and vibration control

Tight dimensional tolerances that reduce secondary machining

Refined surface finish that supports longer service life

Consistency across batches for reliable production output

These characteristics make TGP bars a preferred choice for precision-driven operations.

Illinois Supply and Manufacturing Support

Access to consistent, high-quality TGP material is essential for maintaining production schedules and quality standards. Illinois manufacturers benefit from regional sourcing that supports faster response and dependable material availability.

Mozaic Precision Metals supports Illinois operations with:

ISO-compliant processing practices

certified and traceable material options

precision grinding and polishing expertise

reliable lead times for ongoing production

Regional support helps reduce downtime and maintain supply continuity.

Illinois TGP Bar Supplier | Mozaic Precision Metals

TGP (Turned, Ground & Polished) bars play a key role in Illinois’s automotive, aerospace, hydraulic, medical, and industrial manufacturing sectors. Their straightness, surface quality, and dimensional accuracy make them essential for precision shafts, rods, and critical mechanical components.

Mozaic Precision Metals provides Illinois manufacturers with dependable TGP bar supply, technical support, and consistent turnaround for demanding applications.