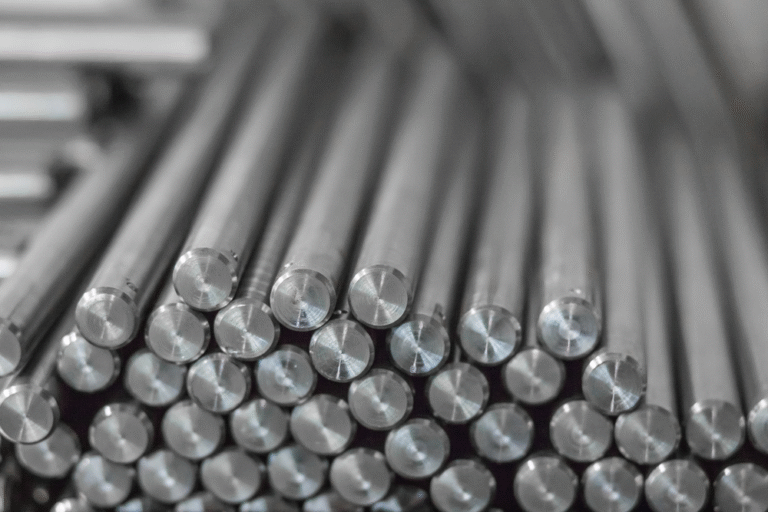

XM-19 (Nitronic 50) Bar Stock for High-Strength Shafting and Machined Components

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Missouri’s medical, aerospace, automotive, and energy industries require access to precision ground bars that guarantee performance and consistency. Whether for surgical implants, turbine shafts, or custom machined components, choosing the right supplier ensures tight tolerances, certified alloys, and dependable delivery.

Precision ground bars are the foundation of high-performance parts because they provide:

Tight Tolerances – minimizing costly machining corrections.

Straightness & Roundness – improving reliability in rotating and sliding systems.

Smooth Surface Finishes – reducing friction and wear.

Consistency – delivering uniform quality across production runs.

Medical – surgical rods, implants, and precision tools.

Aerospace – actuator shafts, turbine pins, and landing gear parts.

Automotive – drivetrain shafts, pins, and fasteners.

Energy & Oilfield – hydraulic rods, pump shafts, and drilling equipment.

General Manufacturing – spindles, arbors, and custom-machined parts.

When sourcing precision ground bars in Missouri, manufacturers should ensure suppliers provide:

ISO-Certified Processes – ensuring compliance and reliability.

Certified Alloys – stainless, titanium, nickel, cobalt chrome, tool steels, and alloys.

Multiple Finishes – CG, PG, CF, CD, TGP, and PSQ.

Fast Delivery & Service – reducing downtime in production.

Mozaic Precision Metals delivers ISO-certified precision ground bars across Missouri, offering certified alloys, a variety of finishes, and competitive lead times. We serve industries ranging from medical and aerospace to automotive and energy with trusted quality.

For Missouri manufacturers, sourcing precision ground bars from a reliable partner ensures quality, efficiency, and compliance with industry standards. With Mozaic Precision Metals, companies gain a dependable supplier of certified bar stock.

Lorem ipsum dolor sit amet, consectetur ad XM-19 stainless steel, also known

Galling is a common failure mechanism in stainless steel components subjected to

Why Swiss Machining Demands the Right 17-4 Condition Swiss lathes place unique